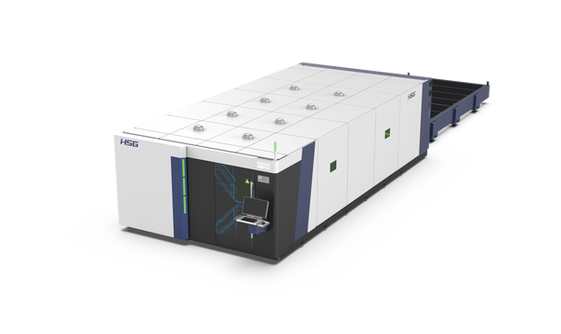

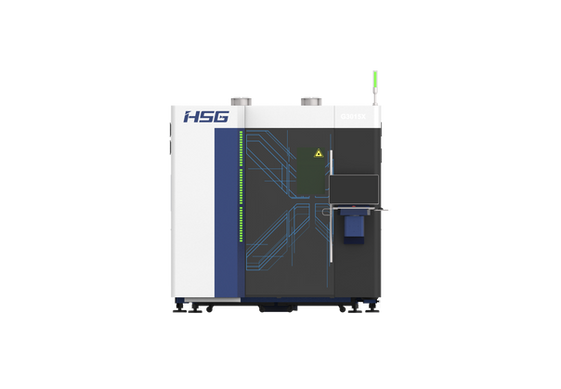

HSG GX Series

Double Exchange Platform Laser Cutter

The HSG GX Series Fibre Laser Cutting Machine is a high-performance cutting solution engineered to deliver exceptional accuracy, speed, and reliability across a wide range of industrial applications. Built with advanced laser technology and precision motion control systems, the GX Series produces clean, precise cuts with excellent edge quality, making it ideal for industries including automotive, aerospace, construction, general fabrication, and machinery manufacturing.

Featuring a rigid, vibration-resistant machine structure and high-response cutting head, the GX Series ensures stable operation and consistent performance even during high-speed processing. This structural strength supports tight tolerances and repeatable results on complex geometries and demanding production schedules.

The GX Series integrates a high level of automation to streamline daily operations and maximise productivity. Intelligent features such as automatic nozzle calibration, adaptive cutting parameters, real-time monitoring, and advanced nesting software reduce manual intervention while improving workflow efficiency and material utilisation.

Capable of cutting a wide range of metals, including stainless steel, carbon steel, aluminium, brass, and copper, the GX Series delivers consistent results with minimal heat-affected zones and reduced secondary processing. Its energy-efficient laser source and low-maintenance design further contribute to lower operating costs and strong long-term return on investment.

Professional Nesting Software

The software offers intuitive operation with drawing functionality, facilitating both manual and automatic nesting processes. It supports a variety of materials and thicknesses, with categorized typesetting for streamlined management. Additionally, it features Excel batch import capability, simplifying data input and enhancing workflow efficiency.

Follow-up Response Technology

Integration of high sensitivity striker plate detection with rapid vibrating sheet tracking, coupled with automatic obstacle avoidance.

Fully Functional Processing Technology

High-speed microjoining, nano microjoining, counterbore technology, and non-inductive perforation. It offers manual and automatic tracing-edge capabilities with an anti-collision beam for safety. Additionally, it efficiently cuts and handles small material fragments, while coaxial visual sensing ensures precise control. Common line cutting reduces waste and conserves energy.

HSG Bus-based Control System

EtherCAT bus enables high-speed response with robust anti-interference capability and simplified electrical maintenance, while automated handling of machine maintenance includes real-time monitoring of key components, ensuring timely reminders for regular upkeep.

TODC-B Dust Extraction Unit

Optional - can be provided with machine by request