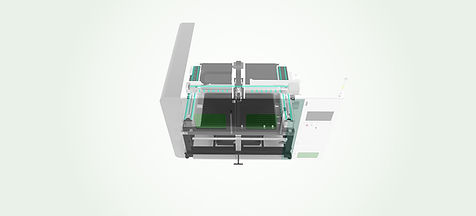

LM 1309 Series

Small Format Laser System

Discover precision and efficiency with Laser Machines' fully enclosed fiber laser cutting machine. Designed for limited spaces, this compact yet powerful cutter offers the full capabilities of a larger machine. Featuring enclosed guarding for safety, a 1300 x 900mm pull-out cutting table, and a 2kW Max Photonics fiber laser source, it ensures unparalleled accuracy and efficiency. Ideal for prototyping, research, small parts manufacturing, education, and pre-production samples, it’s perfect for developing designs, conducting experiments, producing high-precision parts, and teaching advanced techniques—all without needing a full-sized machine. Experience ultimate precision laser cutting in a compact form.

Triangular Steel Welded Bed

This bed uses computer-based finite element analysis to optimise its design, incorporating a triangular steel plate layout for better structural integrity. This makes the bed much stronger and more rigid. Additionally, the welded bed undergoes stress relief annealing, ensuring it is more stable and resistant to deformation, even with its heavier construction.

CypCut Control System

CypCut cutting software is specifically designed for the laser cutting industry, offering deep customisation, ease of use, and a wide range of functions.

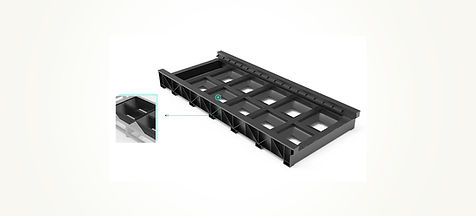

Push/Pull Cutting Draw

The operator can easily perform tasks such as loading, unloading, and slag cleaning, making the process simple and hassle-free.

Dual Drive Dual Screw Configuration

The X-axis is equipped with two guide rails, allowing for faster movement and more precise cutting. This design ensures smooth, straight cuts without wavy lines.

The Y-axis features a dual-drive, dual-screw configuration with four guide rails, providing enhanced stability and smoother operation.

Vertical Lift Door

The ultra-smooth vertical sliding doors move up and down efficiently, optimising space utilisation and saving room.

Automatic Lubrication System

Automatic lubrication of guide rails, sliders, screws and other components.

STANDARD INCLUSIONS

Installation & 3 days training

12 Months on-site support

Extraction fan unit to vent outside.*

Delivery to nearest container port including local delivery & installation

Consumables package

Assist gas connections with Aust. Standard Regulators

*Piping from Fan to outside is Customers responsibility.